Katrangan

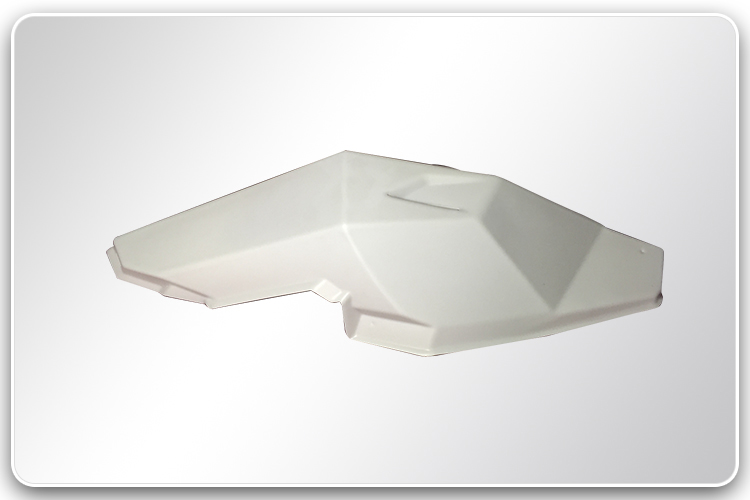

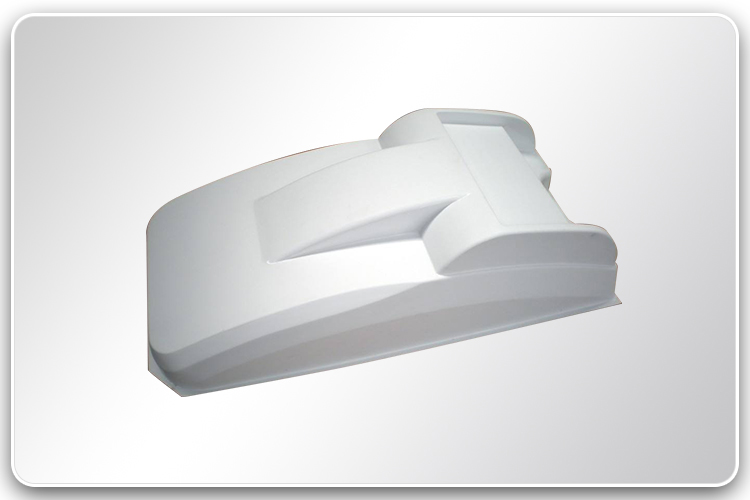

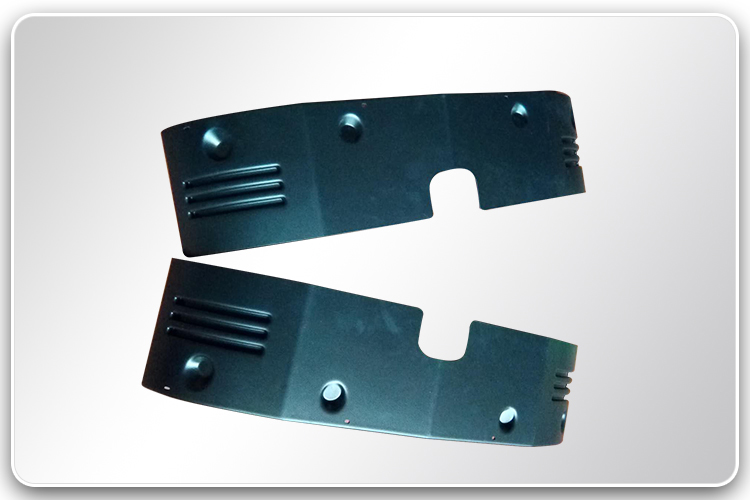

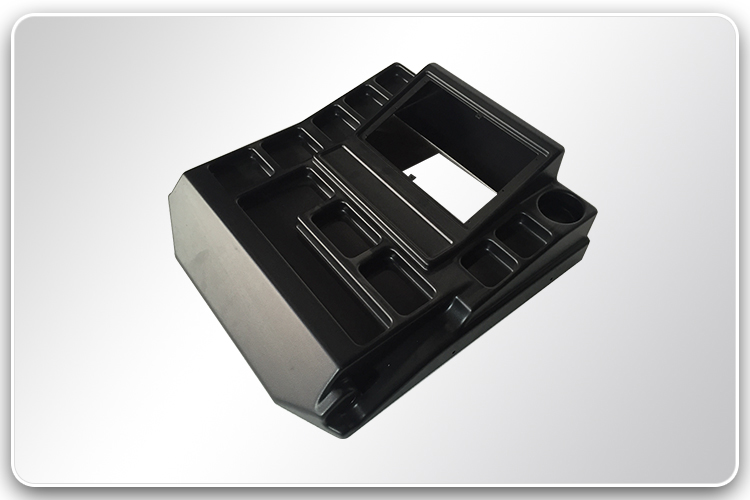

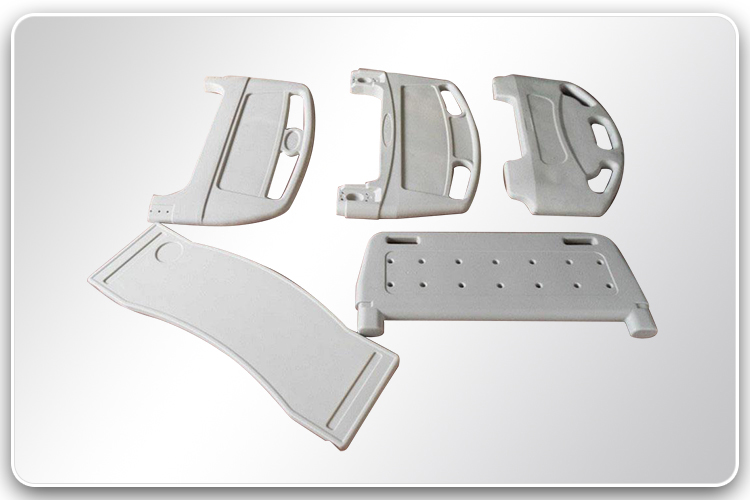

Thermoforming is a manufacturing process whereby a plastic sheet is heated to a pliable forming temperature, formed to a

specific shape in a mold, and trimmed to create a usable product. Auwell has

rich experience in manufacturing and supplying plastic thermoforming parts to

our worldwide clients.

There are two main types of forming process for plastic thermoforming

parts production: vacuum forming and pressure forming. Vacuum forming uses heat

and pressure to draw plastic sheets into its final configuration. Once a sheet

is heated and placed over a mold, a vacuum is used to manipulate it into its

desired shape. Pressure forming has many similarities to vacuum forming, but

has the added benefit of additional pressure. This pressure allows for greater

detail and texture, making it a solid choice when aesthetics is an issue. The

most common way from Auwell plastic thermoforming parts production is vacuum

forming.

Akeh panggunaan sing kasedhiya kanggo bagean termoforming plastik. Salah sawijining morecommon yaiku kemasan, utamane kemasan kaku kanggo panganan lan barang-barang konsumen, nanging akeh aplikasi liyane kalebu otomotif, mesin, instrumen medis, barang putih, perabotan, peralatan fitness lsp.

Produksi komponen termoforming plastik minangka proses sing murah regane dibandhingake karo injeksi plastik, utamane biaya perkakas, ing sawetara kasus, bisa 95% luwih murah dibandhingake cetakan injeksi plastik. Uga, kanthi bunder pangembangan sing luwih cepet. Bahan paling umum kanggo produksi komponen termoforming plastik yaiku ABS. Werna bisa dipesen sadurunge yen jumlahe pesenan memenuhi persyaratan MOQ (biasane1,000kg). Uga, plastik cet bisa uga kasedhiya, saéngga bisa nggawe kustomisasi sing akeh kanggo memenuhi kebutuhan pelanggan.

Technical Specifications

-Materi

ABS,ASA,PC,PEGT,HDPE,PS,PVC,PMMA

-Materi Thickness

0,2mm nganti 8,0mm

Advantages

-Rich Experience

More than 20 years of

experience in Plastic thermoforming parts development and part production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to deliver first sample in 2 weeks.

-Comprehensive Solution Provider

Auwell nyedhiyakake layanan komprehensif kanggo pambangunan bagean termoforming Plastik wiwit ngrancang, liwat prototyping, pangembangan alat / perlengkapan, sampling, produksi massal, lan dhukungan logistik lan pasca jual.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Plastic thermoforming parts orders. Materi

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Jangka Bayaran sing Fleksibel

Kanggo perkakas, istilah pambayaran umum yaiku 50% -50%, tegese celengan 50%, 50% sawise sampel gratis gratis. Produksi formass, kita nawakake syarat pambayaran sing fleksibel, syarat kredit sing cukup bakal diwenehake, klien mung mbayar nalika seneng karo produk sing ditampa. Kanggo proyek jangka panjang, kita nawakake layanan inventaris telpon kanggo syarat pengiriman cepet.

Produk sing gegandhengan

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Plastic Injection Parts

Plastic Injection Parts

Injeksi Plastik Nyalip

Injeksi Plastik Nyalip

Karet & Moulding Silikon

Karet & Moulding Silikon

The following catalogues of plastic injection parts are

the ones which Auwell has produced and supplied to our distinguished worldwide

clients. Please click the relevant pictures for details. Please be advised,

most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик