Description

Rubber & Silicone molding is a manufacturing process whereby an amount

of uncured rubber or silicone is transformed into a usable product.

There are 3 types of Rubber & Silicone molding process:

-Rubber compression molding

Placing a predetermined

amount of rubber compound directly into the mold cavity and then compressing it

into the shape of the cavity by closing the two sides of the mold.

-Cetakan injeksi karet

In this Rubber &

Silicone molding process the uncured rubber compound is heated to a liquid

state before being injected into a mold. The product is released by opening the

mold and closing it again to receive the next injection.

-Rubber transfer molding

Sajrone proses cetakan Karet & Silikon, karet utawa senyawa silikon sing ora diisi dilebokake ing cetakan sing diarani "pot" sadurunge dipeksa liwat aperture menyang akroitas ing bentuk produk sing dikarepake. Nalika ditambani, cetakan kasebut mbedakake produk pungkasan.

Material from Auwell for Rubber & Silicone molding:

-Nitril utawa Buna-N

The most popular and

low-cost solution in Rubber & Silicone molding

-Nitril Hidrogenasi

This is a more expensive

hydrogenated variation of Nitrile polymer, which increases its resistance to

heat, petroleum products, and ozone almost fivefold.

-Ethylene Propylene DieneMonomer (EPDM)

Umume digunakake ing produk karet kanggo sistem uap, segel panel kendharaan, lan sistem rem amarga resistensi dhuwur kanggo cairan rem

-Silicone

Resistant to exposure to

high and low temperatures, is very flexible and has good weather resistance.

-Fluorosililik

Nggabungake kaluwihan silikon temperaturerange kanthi resistensi minyak, bahan bakar, lan solventsfound ing fluorokarbon.

-Neoprene

Minangka multi-purposematerial sing kuwat, bisa digunakake ing pirang-pirang solusi cetakan karet. Iki nduweni sifat tahan api lan abrasi lan asring digunakake kanggo produksi alat transportasi lan transportasi

-Natural Rubber

Produk alami sing diproduksi saka lateks sing asale saka wit karet

-SBR (Styrene butadiene)

One of the more

cost-effective polymers that can be used in rubber molding and is frequently

used in the production of tires, diaphragms, seals and gaskets and the mass

production of other rubber parts

-Fluorokarbon

This relatively expensive

rubber compound combines a wide range of chemical resistance and

high-temperature properties.

-Butil

Has a high resistance to

gas permeability. This makes it the ideal solution in the production of seals

for high-pressure gas and vacuum systems

-Urethane

A fairly high priced, but

commonly used material in applications subject to high pressure and constant

shock loads

Advantages

-Pengalaman Sugih

More than 20 years of

experience in Rubber & Silicone molding parts development and part

production, especially to the European and North American markets, with solid understanding

of the material, technical and quality standards worldwide.

-Cepet Nguripake

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell is able to provide fast prototypes in 5

working days, for simple and small size tooling, we are able to deliver first

sample in 2 weeks.

-Panyedhiya Solusi Komprehensif

Auwell provides

comprehensive services for Rubber & Silicone molding parts development

starting from designing, through prototyping, tooling/fixture development,

sampling, mass production, and to logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection for Rubber & Silicone molding parts orders. Material

certificates include the mill certificate, 3rd party chemical components, and

mechanical property reports, as well as RoHS and REACH reports upon request. We

structure our processes, creating Flow Charts and Control Plans before

production, making sure all QC processes are in accordance with ISO9001-2015

requirements and drawing specifications.

-Jangka Bayaran sing Fleksibel

For tooling, the general

payment term is 50%-50%, meant 50% deposit, 50% after first sample free. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Related Products

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Plastic Injection Parts

Plastic Injection Parts

Plastic Injection Overmolding

Plastic Injection Overmolding

Plastic Thermoforming Parts

Plastic Thermoforming Parts

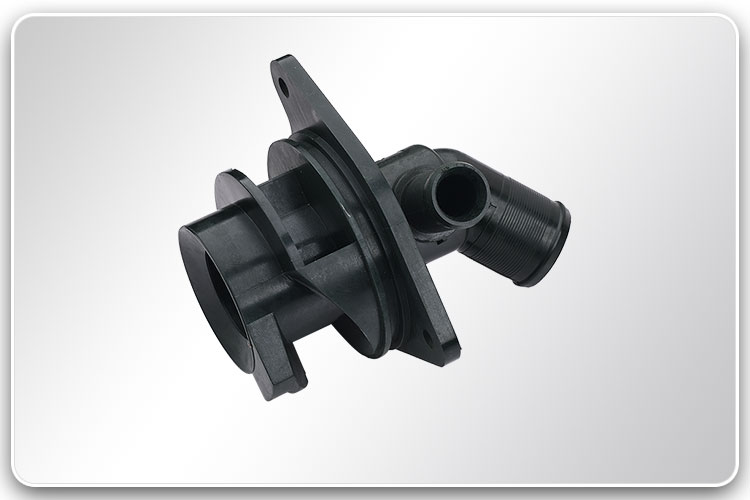

The following catalogues of Rubber & Silicone molding parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик