Garment Racking Logistic Garment iki sing dikembangake kanggo klien Jerman 5 taun kepungkur. Syarat khusus kanggo seri produk tartamtu yaiku nut welding sing kudu diuji kanthi torsi ketat, ana syarat unik kanggo lem utas. Baut kanthi lem utas kudu diimpor saka Jerman utawa, bagean sing bakal dipasang ing gudang mitra kita ing Jerman.

Big order quantity, high quality requirements, reasonable inventory for on-time delivery are the basic requirements from the client, and price needs to be extremely competitive. This series orders are of big challenge for Auwell, as for the big price pressure and inventory requirements, it is required supplier has perfect production plan, strict quality management and effective cost organization, also strong financial capability for inventory management.

The process of Garment Logistic Racking Parts includes 5 steps - cutting, forming, welding, surface treatment and assembling.

-Cutting Process

Kanggo Bagian Racking Logistic Garment iki, stamping minangka cara sing paling umum kanggo blanking bahan.

-Forming Process

Proses pambentuk biasane kalebu mlengkung, doyo, lan panggilingan. Sifat desain bagean nemtokake metode sing digunakake. Deburring minangka prosedur penting sadurunge welding lan assembling.

-Ngumpul

For Garment Logistic Racking Parts, the main process of assembling is welding and screwing. Fixtures need to be pre-designed and made to ensure a product with no distortion after welding. A set of test gauges are pre-developed for quality inspection, ensuring the complete functionality of the product.

-Perawatan lumahing

Nganti saiki, mung perawatan lumahing seng-seri kanggo seri produk iki. Perawatan lumahing liyane kalebu elektroforesis (KTL), nutupi bubuk, lukisan kasedhiya miturut panyuwunan.

Technical Specifications

-Material

SPHC steel sheet, high grade fastener

-Perawatan lumahing

Zinc plating

-Other specifications

Capable in designing and developing necessary tools for Garment Logistic Racking Parts including forming dies, fixtures for welding, and test gauges for mass production QC. CMM is available for sample dimensional inspection. Perawatan lumahing includes KTL, powder coating, painting and zinc plating. Flow Chat and Control Plan will be submitted to the client for discussion before production.

Kaluwihan

-Rich Experience

More than 5 years of experience in Garment Logistic Racking Parts development and production, especially to the European markets, with solid understanding of the material, technical and quality standards worldwide.

-Fast Turnaround

Umume, kita nyedhiyakake kutipan sajrone 3 dina kerja. Nggabungke teknologi lan fasilitas manufaktur paling anyar, Auwell bisa nyedhiyakake prototipe cepet mung sajrone 3 minggu kanggo proyek sederhana.

-Panyedhiya Solusi Komprehensif

Auwell provides comprehensive services for Garment Logistic Racking Parts starting from designing, through prototyping, tooling/fixture development, sampling, mass production, and to logistic and post-sale support.

-Kebijakan QC Kaku

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection to Garment Logistic Racking Parts orders. Material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

-Jangka Bayaran sing Fleksibel

Pembayaran alat kudu dibayar sadurunge. Kanggo produksi massal, kita nawakake syarat pembayaran sing fleksibel, syarat kredit sing cukup bakal diwenehake, klien mung mbayar nalika seneng karo produk sing ditampa. Kanggo proyek jangka panjang, kita nawakake layanan inventaris telpon kanggo syarat pangiriman cepet.

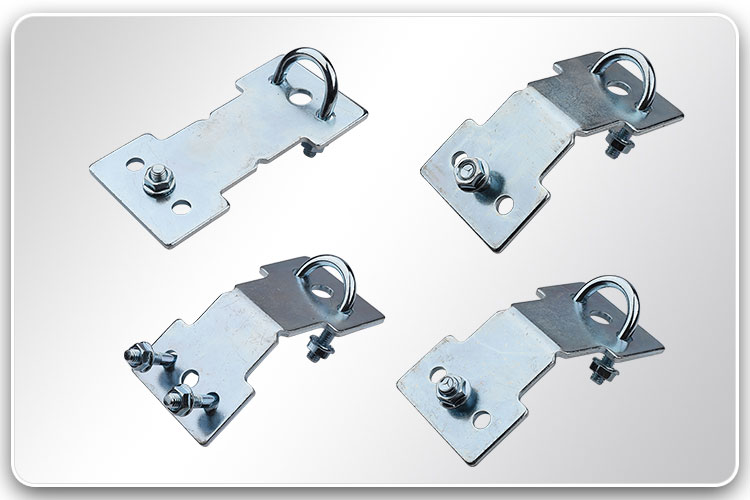

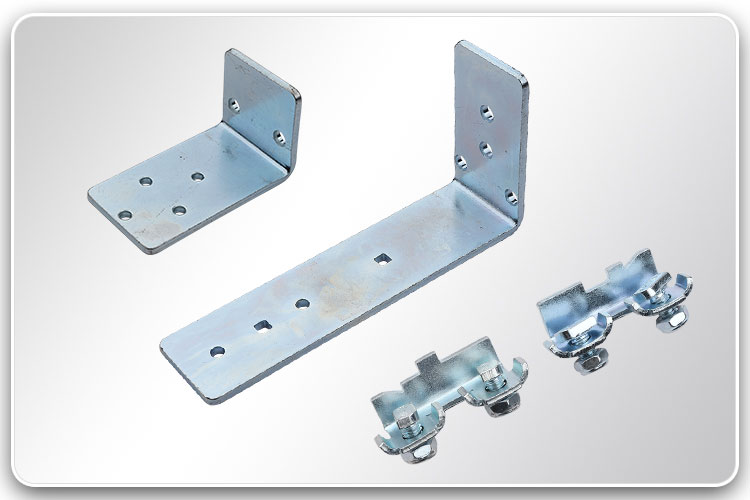

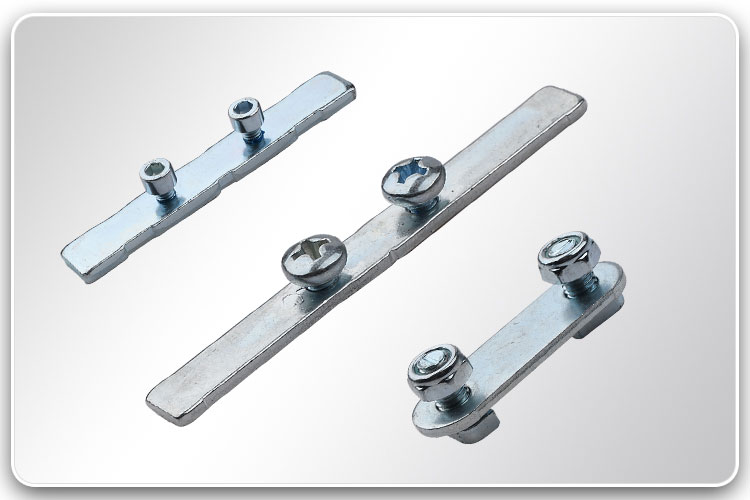

Katalog babagan Garment Racking Logistic Garment ing ngisor iki minangka sing diprodhuksi lan diwenehake Auwell kanggo klien sing misuwur ing saindenging jagad. Klik gambar sing cocog kanggo rincian. Elingi, umume produk mung kanggo demonstrasi.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик