Gambar & puteran jero minangka proses produksi tambahan kanggo stamping. Nalika produk kanthi bentuk kothong bentuk-cangkir, kothak, lan sudhut mlengkung liyane sing ora bisa dibentuk kanthi proses stamping, utawa, yen ambane bagean sing digambar ngluwihi diametere, gambar nggambar lan jero bisa dadi proses pabrikan sing pas .

Proses nggambar & muter ing jero mbutuhake materi dadi baja karbon sithik kanthi elongasi dhuwur kanggo kinerja sing apik banget. Dadi, baja karbon sithik bakal dadi pilihan sing paling apik, jelasaluminum lan tembaga minangka bahan sing apik kanggo proses iki. Baja stainless uga bisa dadi pilihan kanggo nggambar lan proses Spinning jero nanging mbutuhake perawatan panas supaya luwih alus sadurunge proses sabanjure.

The surface

treatment for deep drawing & spinning parts can be:

-Polesan

-Zinc-plating

-Plating nikel

-Chrome plating

-Plating perak

-KTL

-Galvanisasi celup panas

-Lukisan

-Lapisan bubuk

-Anodizing

Auwell duwe morethan 20 taun sajrone nggambar lan produksi bagean utama. Pengalaman sing sugih ing Auwell, efektif biaya, fastturnaround lan kapasitas produksi gedhe uga term pembayaran sing apik banget entuk reputasi saka klien.

Kaluwihan Kompetitif

-Rich Experience

More than 20 years of experience in deep drawing & spinning parts

development and production, especially to the European and North American

markets, with solid understanding of the material, technical and quality

standards worldwide.

-Fast Turnaround

Umume, kita nyedhiyakake kutipan sajrone 3 dina kerja. Nggabungke teknologi lan fasilitas manufaktur paling canggih, Auwell bisa nyedhiyakake fastprototypes kanggo nggambar & bagean muter kanthi jero mung 2 minggu kanggo proyek sederhana.

-Comprehensive Solution Provider

Auwell nyedhiyakake layanan lengkap kanggo pangembangan gambar & muter bagean wiwit saka ngrancang, liwat prototyping, tooling / fxturedevelopment, sampling, produksi massal, lan dhukungan logistik lan post-sale.

-Kebijakan QC Kaku

Kebijakan kualitas sing paling ketat diwiwiti saka kontrol materi, lan diikuti nganti dipriksa sadurunge dikirim. Sertifikat material kalebu sertipikat pabrik, komponen kimia pihak katelu, lan laporan mekanik mekanik, uga laporan RoHS lan REACH yen dijaluk. Laporan liyane kalebu laporan dimensi, kekandelan perawatan permukaan, lan test kabut uyah, lsp. Kita nyusun proses, nggawe Grafik Aliran lan Kontrol Plans sadurunge produksi, priksa manawa kabeh proses QC sesuai karo persyaratan ISO9001-2015 lan spesifikasi gambar.

-Jangka Bayaran sing Fleksibel

Tooling payments need to be pre-paid. For mass production, we offer

flexible payment terms, reasonable credit terms will be given, the client only

pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

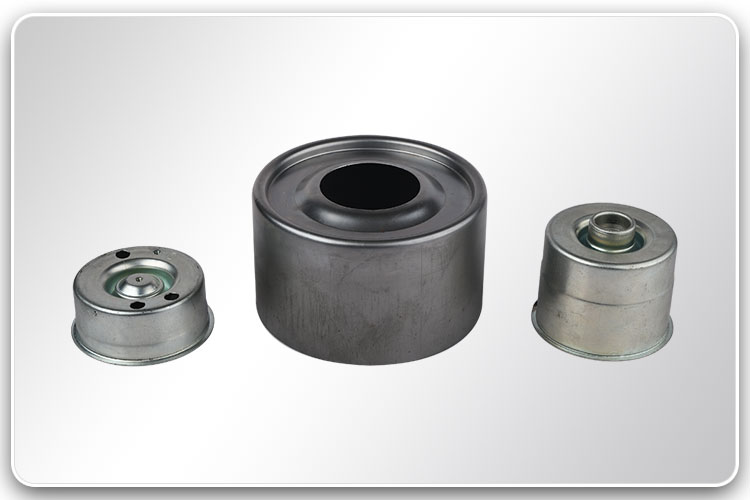

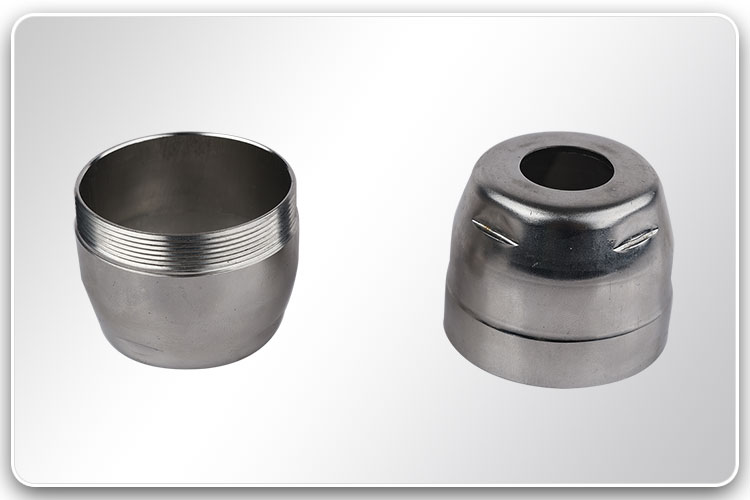

The deep drawing & spinning parts display on this section are some of

the products Auwell has developed for our clients, all of the stamping parts

are OEM made, following products are only for demonstration purpose. If the

clients have the deep drawing & spinning parts need to be developed, it is

warmly welcome to contact us for details.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик