Katrangan

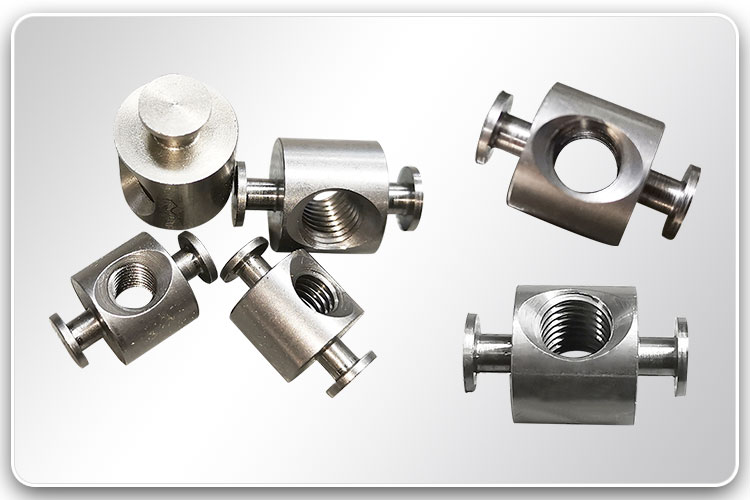

Turning Parts for Spannring are the essential components for clamping ring products. If the closing side of the ring is jointed with saddle and bolt, one clamping ring set consists of generally 4 turning parts. Φ12mm and Φ14mm are the most popular diameters. A set of clamping ring consists 2 of turning parts for the clamping rings, for Φ12mm diameter, one with 6.5mm section hole and M6 thread hole for another, likewise, Φ8.5mm holes and M8 thread holes for Φ14mm turning parts for the clamping rings.

Carbon steel turning parts for the clamping rings have zinc plated surfaces, the default being white zinc plating. For easy identification, the turning parts with thread holes are coated with yellow zinc plating.

Titik kritis kanggo muter bagean kanggo kontrol dering clamping kalebu toleransi diameter area lengen, kualitas bolongan tapak, lan burr ing sekitar area nutul bolongan utas. Sanajan katon sederhana, tanpa proses lan mesin sing bener, masalah kualitas bisa gampang muncul.

Kanthi 15 taun bagean-bagean ngowahi profesional kanggo pengalaman produksi cincin clamping, Auwell wis ngembangake cara paling efisien kanggo ngasilake bagean-bagean puteran kasebut.

Video ing ngisor iki nuduhake proses manufaktur Turning Parts kanggo Spannring:

Saiki, 100% Bagian Turning kanggo Spannring diekspor menyang Jerman kanggo klien sing misuwur. Kanthi nggunakake teknologi lan pamrograman sing dioptimalake, produk kita kabukten nduweni kualitas apik sanajan rega murah. Auwell bangga karo produktivitas sing dhuwur kanggo ngasilake produk kasebut kanthi efektif.

Bagian Turning kanggo produk Spannring sing ditampilake digawe khusus kanggo klien sing misuwur. We seneng nawakake rega kompetitif kanggo kabeh pitakon saka calon klien.

Technical Specifications

-Material: ST12, ST37, Q235B, Stainless steel 304, 316L or upon request

-Puteran bagean: Diameter: Φ12mm kanthi utas M6 utawaΦ14mm kanthi utas M6 utawa miturut panjaluk

-Surface treatment: zinc plating, or blanc for stainless steel

-Paket: kantong plastik, karton banjur kothak kayu.

Advantages

-Rich Experience

Luwih saka 15 taun pengalaman ing bagean-bagean iki kanggo pangembangan ring clamping lan produksi, utamane kanggo pasar Eropa. Kanthi pangerten sing kuat babagan materi, standar teknis lan kualitas ing saindenging jagad.

-Cepet Nguripake

Generally, we provide a quotation within 2 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide turning parts for clamping rings samples in just a week.

-Panyedhiya Solusi Komprehensif

Auwell provides comprehensive services for turning parts for clamping rings projects starting from designing, through prototyping, sampling, mass production, and to logistic and post-sale support.

-Kebijakan QC Kaku

Kawicaksanan kualitas sing paling ketat diwiwiti saka kontrol materi, lan banjur ditindakake nganti inspeksi pra-pengiriman pungkasan. Sertifikat materi kalebu sertifikat pabrik, komponen kimia pihak katelu, lan laporan properti mekanik, uga laporan RoHS lan REACH sing dijaluk. Laporan liyane kalebu laporan dimensi, kekandelan perawatan permukaan, lan laporan tes kabut uyah, lsp. Kita nyusun proses, nggawe Grafik Aliran lan Rencana Kontrol sadurunge produksi, priksa manawa kabeh proses QC sesuai karo persyaratan ISO9001-2015 lan spesifikasi gambar.

-Flexible Payment Term

For mass production, we offer flexible payment terms, reasonable credit terms will be given, the client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

Related Products

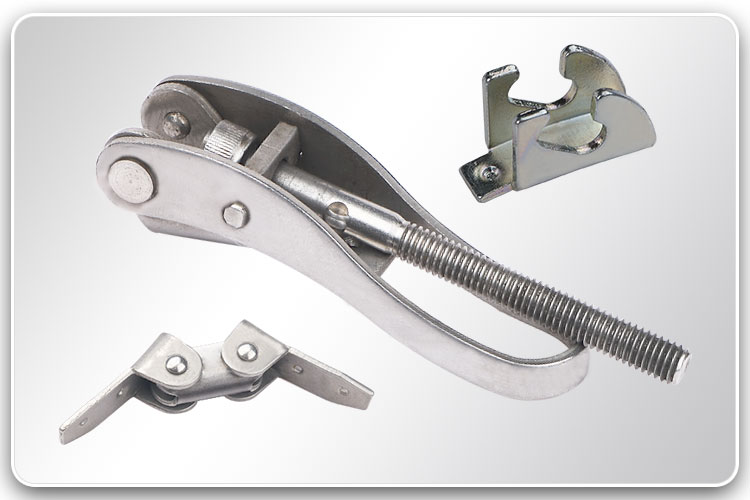

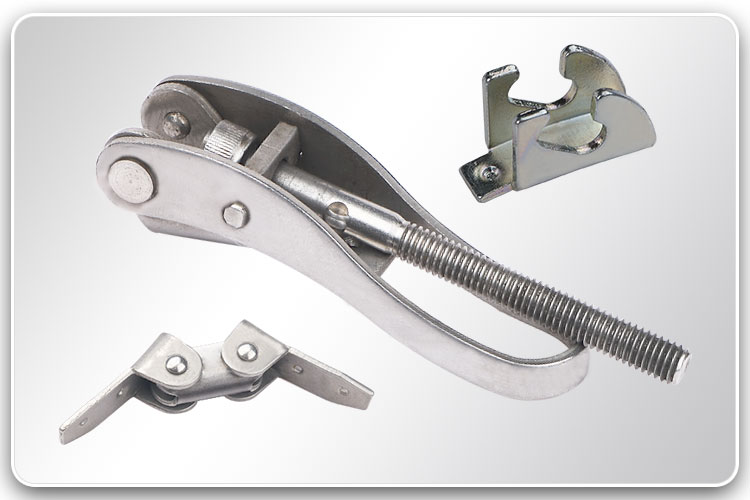

Saddle for Clamping Rings

Saddle for Clamping Rings

Fast Connector for Clamping Rings

Fast Connector for Clamping Rings

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик