Katrangan

Casting minangka proses manufaktur sing bahan cairan biasane diwutahake menyang cetakan, sing ngemot hollowcavity saka bentuk sing dipengini, lan banjur diidini padhet. Partis solidified uga dikenal minangka casting, sing dibuwang utawa rusak saka cetakan kanggo ngrampungake proses kasebut.

Logam sing paling umum sing diolah kanggo casting yaiku aluminium lan besi cor. Nanging, logam liyane, kayata baja tahan karat, baja campuran, tembaga, kuningan, magnesium, lan seng, uga digunakake kanggo ngasilake casting ing pengecoran.

Casting is most commonly used for making complex shapes that would be

difficult or uneconomical to make via other methods. The casting process

typically includes 4 steps - cutting, forming, assembling, and surface

treatment.

-Mold making

In the casting process,

a pattern is made in the shape of the desired part. Simple designs can be made

in a single piece or solid pattern. More complex designs are made in two parts,

called split patterns. The pattern is made of wax, wood, plastic, or

metal. The molds are constructed through several different processes depending on

the type of foundry, metal to be casted, the number of parts to be produced,

size of the casting, and complexity of the casting.

- Melting

Melting is performed in

a furnace. The process includes melting the charge, refining the melt, adjusting

the melt chemistry, and tapping into a transport vessel. Refining is done to remove harmful gases and elements from the molten metal

to avoid casting defects.

-Pouring

In a foundry, molten

metal is poured into molds. Pouring can be accomplished with gravity, or it may be assisted with a

vacuum or pressurized gas.

- Shakeout

Komponen logam sing padhet banjur dicopot saka cetakan. Yen cetakan adhedhasar pasir, iki bisa ditindakake kanthi goyang utawa digulung.

- Degating

Gelar yaiku nyopot kepala, balapan, gerbang, lan riser saka casting. Para pelari, gerbang, lan riser bisa uga ngilangi obor, pita, utawa pisau keramik.

-Ngobati panas

Heat treating is a group

of industrial and metalworking processes used to alter the physical, and

sometimes chemical, properties of a material.

-Surfacecleaning

Sawise degating lan perawatan panas, wedhi utawa media cetakan liyane bisa uga tetep ana ing casting. Kanggo ngilangi sisa-sisa cetakan, lumahing wis di resiki nggunakake proses blasting. Akeh bahan sing bisa digunakake kanggo ngresiki permukaan cast, kalebu baja, zat besi, logam campuran liyane, oksida aluminium, manik kaca, cangkang kenari, bubuk manggang, lan liya-liyane.

- Finishing

Langkah pungkasan ing proses casting biasane kalebu mecah, sanding, utawa mesin komponen kanggo nggayuh akurasi dimensi, bentuk fisik, lan finish permukaan sing dipengini.

Spesifikasi Teknis

-Bahan kanggo casting

Iron, mild steel, alloy

steel, stainless steel, aluminum, bronze, brass, and zinc.

-Following processes are available for producing casting parts upon the

nature of the design.

ØPengecoran pasir - Cetakan pasir sing ana gandhengane ijo utawa resin.

ØLost-foam casting — Polystyrene pattern with a mixture of ceramic and sand mold.

ØCasting investasi - Lilin utawa pola korban sing padha karo cetakan keramik.

ØPengecoran cetakan keramik - Cetakan plester.

ØCasting proses V - Vakum nganggo plastik termoform kanggo mbentuk cetakan pasir. Ora dibutuhake kelembapan, lempung utawa resin.

ØDie casting — Metal mold.

ØBillet (ingot) casting — Simple mold for producing ingots of metal, normally for use in other foundries.

Except providing our clients with casting parts, most

of products Auwell supplies with further machining and surface treatment

service.

Forging is a manufacturing process involving the shaping of metal using

localized compressive forces. Generally, Auwell does not offer forging, but only

using forged parts as pre-material for further processing.

Advantages

-Pengalaman Sugih

More than 20 years of

experience in casting products development and production, especially to the

European and North American markets, with solid understanding of the material,

technical and quality standards worldwide.

-Fast Turnaround

Umume, kita nyedhiyakake akuotasi sajrone 3 dina kerja. Nggabungake teknologi manufaktur lan fasilitas paling anyar, Auwell bisa nyedhiyakake prototipe cepet mung sajrone 2 minggu kanggo proyek sederhana.

-Panyedhiya Solusi Komprehensif

Auwell nyedhiyakake layanan komprehensif kanggo proyek casting wiwit ngrancang, liwat prototipe, pangembangan alat / perlengkapan, sampling, produksi massal, lan dhukungan pasca penjualan.

-Kebijakan QC Kaku

Kualitaspolicy sing paling ketat diwiwiti saka kontrol material, lan banjur dipriksa nganti pungkasan. Kanggo ngontrol kualitas casting bagean, kita nyedhiyakake laporan tes kalebu komponen kimia, properti mekanik, tes X-ray, laporan analisis metalografi lsp. Kanggo inspeksi dimensi, kita nawakake laporan 3Dscanning, uga CMM kasedhiya kanggo inspeksi. Kita nyusun proses, nggawe Grafik Alur lan Rencana Kontrol sadurunge produksi, nggawe kabeh proses QC sesuai karo persyaratan ISO9001-2015 lan nggambarake spesifikasi.

-Flexible Payment Term

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

Applications

Produk pabrikan casting wis digunakake ing meh kabeh industri kayata:

- Aerospace and defense

-Otomotif

-Mesin Pertanian

- Energy

- Electronics

-Konstruksi

-Transportasi

- Industrial

-Produk Konsumen

The following catalogues of casting products are the

ones which Auwell has produced and supplied to our distinguished worldwide

clients. Please click the relevant pictures for details. Please be advised,

most of the products are for demonstration purpose only.

Stainless Steel Investment Casting

Stainless Steel Investment Casting

Casting Stainless Steel kanggo GEBO

Casting Stainless Steel kanggo GEBO

Steering Knuckle

Steering Knuckle

Forging Sambungan Sambungan

Forging Sambungan Sambungan

Forging Wheel Hub

Forging Wheel Hub

AGV Aluminum Base

AGV Aluminum Base

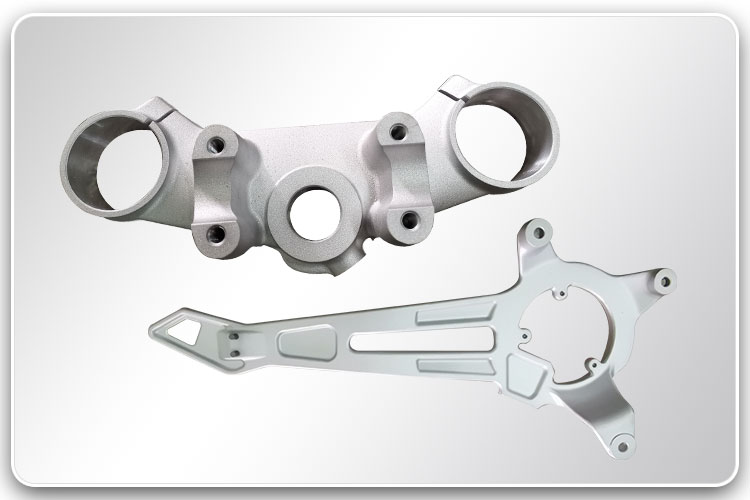

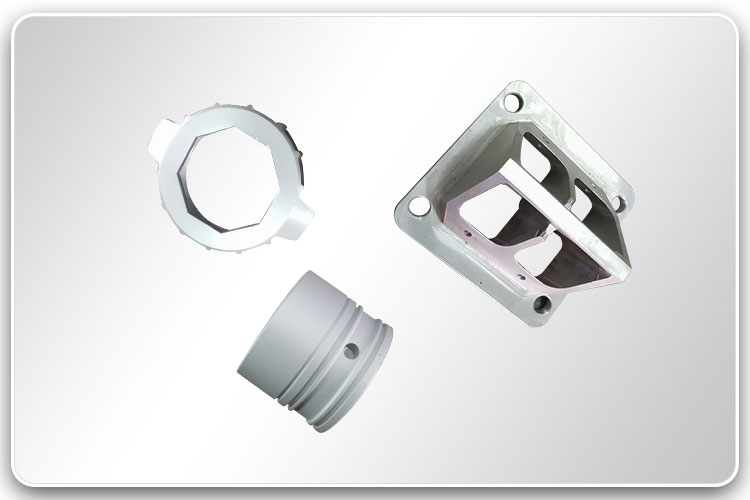

Alu. Gravity & Sand Casting

Alu. Gravity & Sand Casting

Brass Gravity& Sand Casting

Brass Gravity& Sand Casting

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик