Katrangan

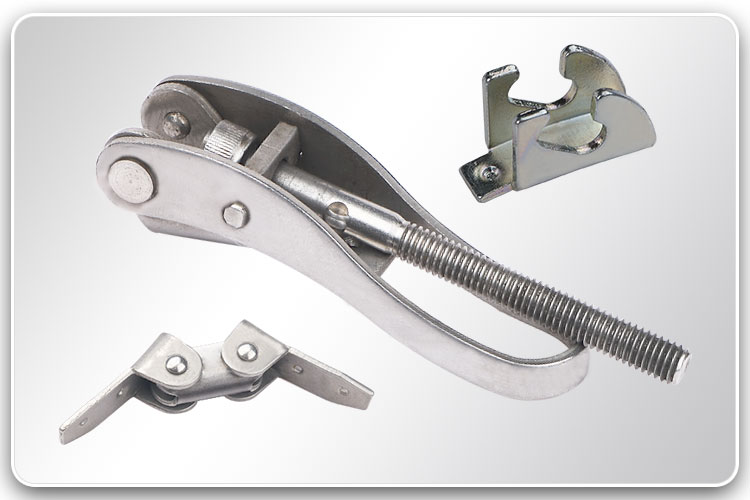

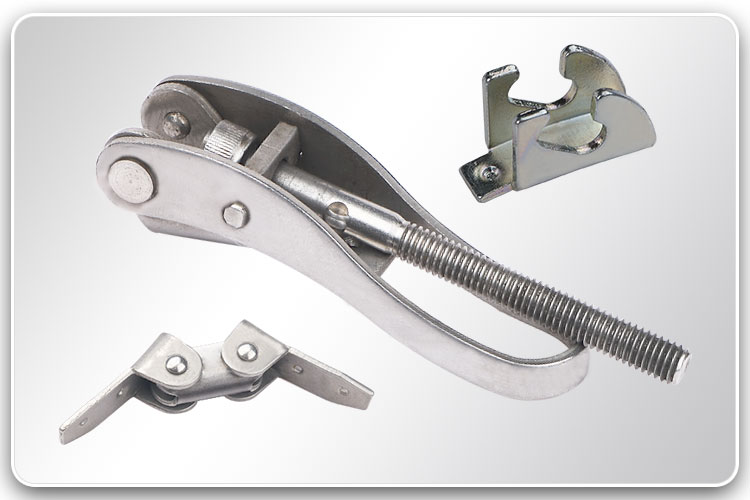

The Stamping Parts for Spannring is the critical component for clamping ring products. Each clamping ring consists of at least 4 saddle parts. The Stamping Parts for Spannring is directly assembled with the clamping ring parts through butt welding followed by hand welding for reinforcement.

The essential control points for the Stamping Parts for Spannring are the tolerance for the slots and the height of the butting welding bulges. The slot contact point with the turning parts arm need to be pressed in, making sure that the turning parts can rotate freely while being held in place. The definite and consistent height of the welds is the guarantee for high welding quality.

Auwell has more than 15 years of experience in manufacturing and supplying Stamping Parts for Spannring product, at this moment, 100% of products exported to Germany for our distinguished clients. Equipped with a progressive die machine, Auwell can produce Stamping Parts for Spannring parts efficiently for cost-effective reasons. Progressive stamping is the guarantee of quality consistency.

By using optimized technology and programming, our saddle for clamping rings products have been proven as excellent in quality at an affordable price. Auwell is proud of its high productivity for producing these products in a cost-effective way.

Video ing ngisor iki nduduhake cara profesional ing saddle kanggo produksi cincin clamping:

The Stamping Parts for Spannring products displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

Technical Specifications

-Material: ST12, ST37,

Q235B, Stainless steel 304, 316L or upon request

-Saddle thickness: 2.5mm

-Lumahing: rustprotection minyak ringan

-Package information:

Available upon request

Kaluwihan

-Rich Experience

Luwih saka 15 taun pengalaman ing saddle kanggo clamping pengembangan produk lan produksi, utamane kanggo pasar Eropa. Kanthi pangerten sing kuat babagan materi, standar kualitas teknis lan global ing saindenging jagad.

-Fast Turnaround

Umume, kita nyedhiyakake akuotasi sajrone 3 dina kerja. Nggabungke teknologi manufaktur lan fasilitas paling anyar, Auwell bisa nyedhiyakake prototipe cepet kanggo cincin forclamping saddle mung 3 minggu kanggo bagean saddle.

-Comprehensive Solution Provider

Auwell nyedhiyakake layanan lengkap kanggo saddle kanggo proyek ring clamping wiwit saka desain, liwat prototyping, pangembangan alat / perlengkapan, sampling, produksi massal, lan dhukungan logistik lan post-sale.

-Rigid QC Policies

Kualitaspolicy sing paling ketat diwiwiti saka kontrol material, lan banjur dipriksa nganti pungkasan. Sertifikat material kalebu sertifikat pabrik, komponen kimia pihak katelu, lan laporan properti mekanik, uga laporan RoHSand REACH sing dijaluk. Kita nyusun proses, nggawe Rencana Kontrol Grafik Aliran sadurunge produksi, priksa manawa kabeh proses QC sesuai karo persyaratan ISO9001-2015 lan spesifikasi gambar.

-Flexible Payment Term

Pembayaran alat kudu dibayar sadurunge. Kanggo produksi massal, kita nawakake syarat pambayaran sing fleksibel, syarat sing bisa dibayar bisa diwenehake, klien mung mbayar nalika seneng karo produk sing ditampa. Kanggo proyek jangka panjang, kita nawakake layanan inventaris telpon kanggo syarat pangiriman cepet.

Related Products

Konektor Cepet kanggo Dering Clamping

Konektor Cepet kanggo Dering Clamping

Turning Parts for Clamping Rings

Turning Parts for Clamping Rings

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик