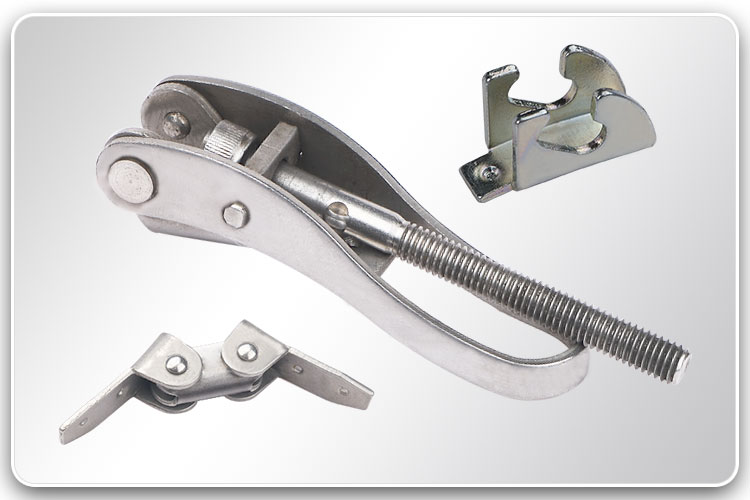

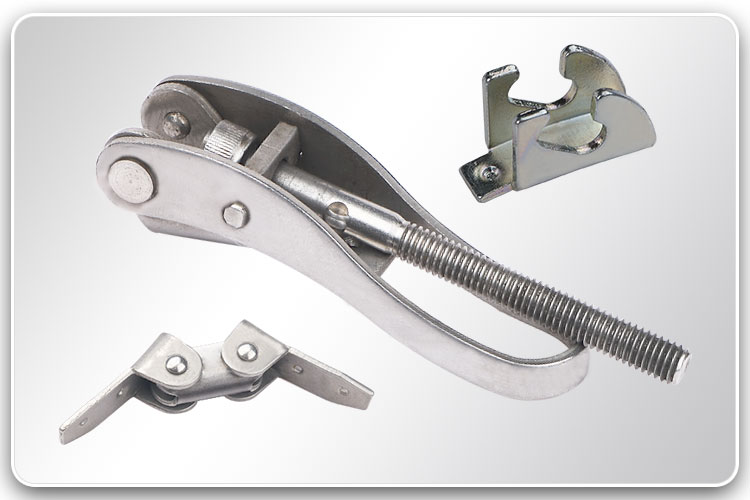

Description

The Stamping Parts for Clamping Rings is the critical component for clamping ring products. Each clamping ring consists of at least 4 saddle parts. The Stamping Parts for Clamping Rings is directly assembled with the clamping ring parts through butt welding followed by hand welding for reinforcement.

Titik kontrol penting kanggo Stamping Parts kanggo Clamping Rings yaiku toleransi kanggo slot lan dhuwure bulge welding butting. Titik kontak slot karo lengen bagean puter kudu ditekan, priksa manawa bagean puteran bisa muter kanthi bebas nalika ditahan. Dhuwur sing pasti lan konsisten kanggo las minangka jaminan kualitas las sing dhuwur.

Auwell has more than 15 years of experience in manufacturing and supplying Stamping Parts for Clamping Rings product, at this moment, 100% of products exported to Germany for our distinguished clients. Equipped with a progressive die machine, Auwell can produce Stamping Parts for Clamping Rings parts efficiently for cost-effective reasons. Progressive stamping is the guarantee of quality consistency.

Kanthi nggunakake teknologi lan pamrograman sing dioptimalake, pelana kanggo produk dering clamping wis kabukten kualitas kanthi rega sing terjangkau. Auwell bangga karo produktivitas sing dhuwur kanggo ngasilake produk kasebut kanthi efektif

Following video demonstrates our professional way in saddle for clamping rings production:

The Stamping Parts for Clamping Rings displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

Technical Specifications

-Bahan: ST12, ST37, Q235B, Baja tahan karat 304, 316L utawa miturut panjaluk

-Saddle thickness: 2.5mm

-Lumahing: rustprotection minyak ringan

-Informasi paket: Kasedhiya yen dijaluk

Advantages

-Pengalaman Sugih

More than 15 years of

experience in saddle for clamping rings products development and production, especially

to the European markets. With solid understanding of the material, technical

and quality standards worldwide.

-Cepet Nguripake

Umume, kita nyedhiyakake akuotasi sajrone 3 dina kerja. Nggabungke teknologi manufaktur lan fasilitas paling anyar, Auwell bisa nyedhiyakake prototipe cepet kanggo cincin forclamping saddle mung 3 minggu kanggo bagean saddle.

-Panyedhiya Solusi Komprehensif

Auwell provides

comprehensive services for saddle for clamping rings projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-Kebijakan QC Kaku

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

Tooling payments need to

be pre-paid. For mass production, we offer flexible payment terms, reasonable

credit terms will be given, the client only pays when they are happy with the

product they received. For long-term projects, we offer call-off inventory

services for fast delivery requirements.

Related Products

Konektor Cepet kanggo Dering Clamping

Konektor Cepet kanggo Dering Clamping

Nguripake Bagian kanggo Dering Clamping

Nguripake Bagian kanggo Dering Clamping

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик