Description

Sheet metal fabrication is the process of forming and producing parts from a metal sheet. Sheet metal fabrication processes produce highly durable components well-suited for both functional prototypes and end-use production. Our custom sheet metal services offer a cost-effective and on-demand solution for your manufacturing needs. Fabrication services range from low-volume prototyping to high-volume production runs with significant cost savings.

Proses kasebut biasane kalebu 4 langkah - nglereni, mbentuk, ngrakit, lan perawatan permukaan.

-Proses Nglereni

We offer various cutting options with thickness ranged from 1mm to 150mm, this includes oxygen cutting with a maximum thickness capacity of 150mm for carbon steel. We also offer plasma cutting, laser cutting, water jet cutting, wire cutting, shearing, and/or die-cutting, we may also use punching for holes. Laser cutting is the preferred option for cutting sheets, it’s speed and precision guarantees spectacular results. With thicker materials, plasma cutting may be favorable for it’s speed. This method is normally used when the material thickness is over 10mm.

-Proses Pembentukan

The forming process typically includes bending, hydraulic press forming with die, punching, and milling. The nature of the parts’ design determines the method used. Deburring is an essential procedure before welding and assembling.

-Assembling

Kanggo pabrikan logam sheet, proses utama assembling yaiku welding. Jadwal kudu dirancang sadurunge lan digawe kanggo njamin produktanpa distorsi sawise ngelas. Sawetara wilayah mbutuhake panggilingan sawise dirakit. Alat pangukur tes wis dikembangake kanggo pamriksa kualitas, supaya fungsionalitas lengkap kanggo produk.

-Surface Treatment

The normal surface treatment process for sheet metal fabrication products include electrophoresis (KTL), powder coating, painting, and zinc plating. For large products like chassis, painting is widely used whereas for middle size parts, the KTL process is preferred.

For all surface treatment, we offer coating adhesion, thickness, and salt fog tests or, other tests to be conducted upon request.

Anodizing kasedhiya karo bahan aluminium.

Technical Specifications

-Material

Mild steel, stainless steel, copper, brass, aluminum, and alloy steel.

-Machine capacity

Mesin press hidrolik 1,200 ton, mesin stamping 800 ton, kekandelan nglereni bahan nganti 150mm kanggo nglereni oksigen, 60mm kanggo nglereni plasma, lan 25mm kanggo nglereni laser. Ukuran bagean maksimal: 2.000 * 1.500mm

-Spesifikasi liyane

Bisa ngrancang lan ngembangake alat sing dibutuhake kanggo pabrikan logam sheet kalebu nggawe mati, perlengkapan kanggo las, lan pengukur tes kanggo produksi massal QC. CMM kasedhiya kanggo conto conto inspeksi. Perawatan permukaan kalebu KTL, lapisan bubuk, lukisan (Walspar), lan pelapis seng. Dokumen PPAP kasedhiya yen dijaluk.

Kaluwihan

-Rich Experience

Luwih saka 20 taun pengalaman ing produksi lan produksi produk pabrikan logam, utamane kanggo pasar Eropa lan Amerika Utara, kanthi pangerten babagan standar materi, teknis lan kualitas ing saindenging jagad.

-Cepet Nguripake

Generally, we provide a quotation within 3 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide fast prototypes in just 2 weeks for simple projects.

-Panyedhiya Solusi Komprehensif

Auwell nyedhiyakake layanan lengkap kanggo proyek pabrikan logam wiwit saka ngrancang, liwat prototipe, pangembangan alat / perlengkapan, sampling, produksi massal, lan dhukungan logistik lan pasca jual.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection.

Sertifikat materi kalebu sertifikat pabrik, komponen kimia pihak katelu, lan laporan properti mekanik, uga laporan RoHS lan REACH sing dijaluk. Laporan liyane kalebu laporan dimensi, kekandelan perawatan permukaan, lan laporan tes kabut uyah, lsp. Kita nyusun proses, nggawe Grafik Aliran lan Rencana Kontrol sadurunge produksi, priksa manawa kabeh proses QC sesuai karo persyaratan ISO9001-2015 lan spesifikasi gambar.

-Flexible Payment Term

Tooling payments need to be pre-paid. For mass production, we offer flexible payment terms, reasonable credit terms willdiwenehi, klien mung mbayar nalika seneng karo produk sing ditampa. Kanggo proyek jangka panjang, kita nawakake layanan inventaris telpon kanggo syarat pangiriman cepet.

Applications

Produk pabrikan logam lembar wis digunakake ing meh kabeh sektor industri kalebu:

-Aeroangkasa lan pertahanan

-Otomotif

-Mesin Pertanian

-Energy

-Electronics

-Konstruksi

-Transportasi

-Industrial

-Consumer Products

Katalog produk pabrikan logam sheet ing ngisor iki minangka sing diprodhuksi lan diwenehake dening Auwell kanggo para klien terkenal ing saindenging jagad. Klik gambar sing cocog kanggo rincian. Perlu dingerteni, umume produk kanggo nduduhake tujuan kemampuan manufaktur mung.

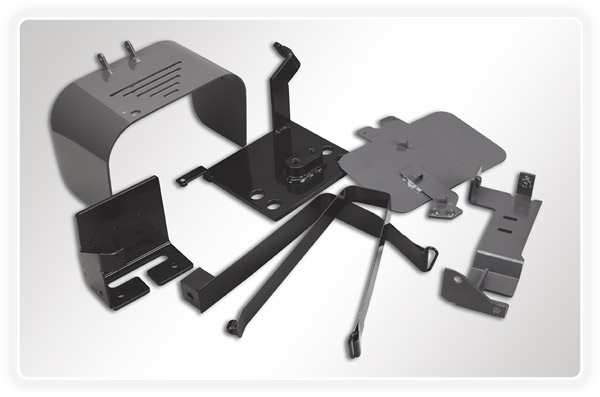

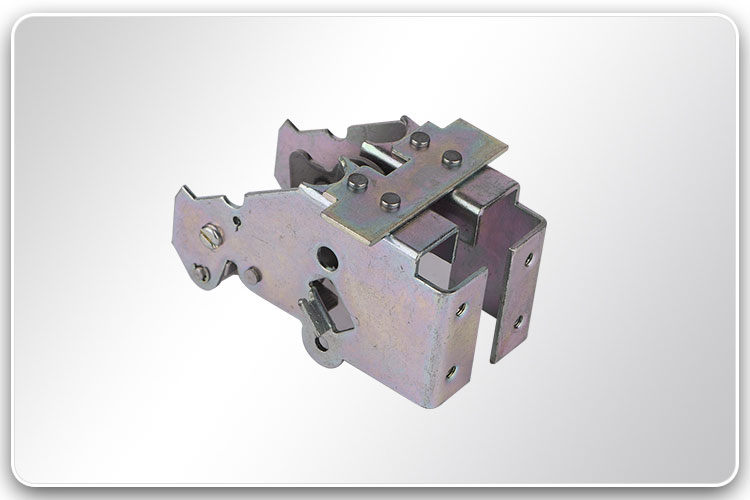

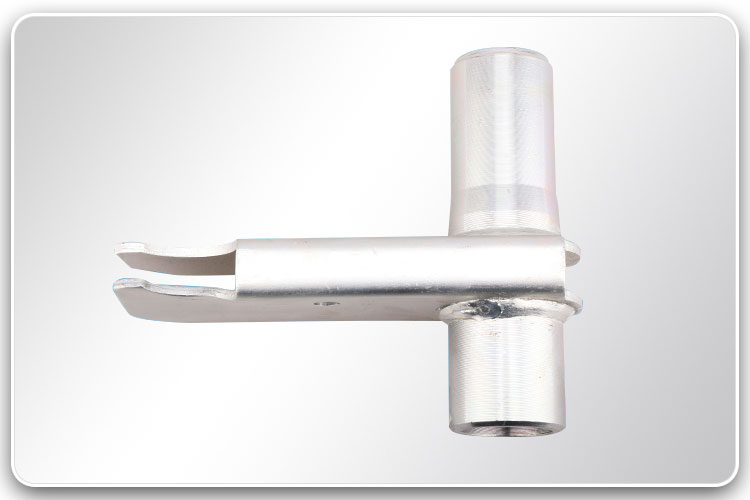

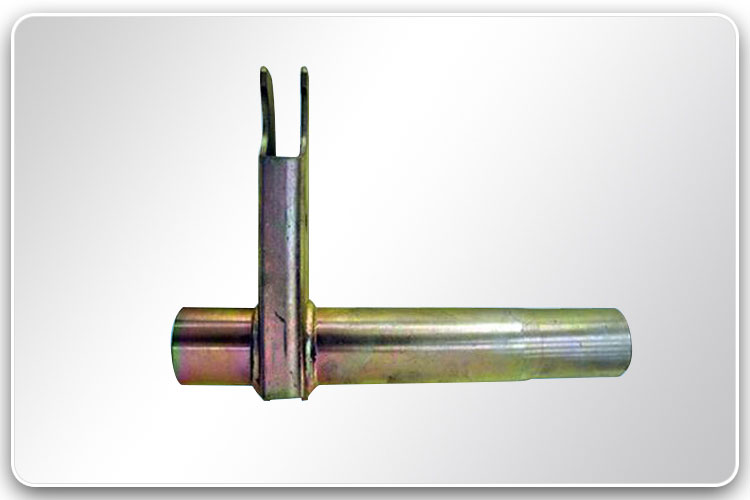

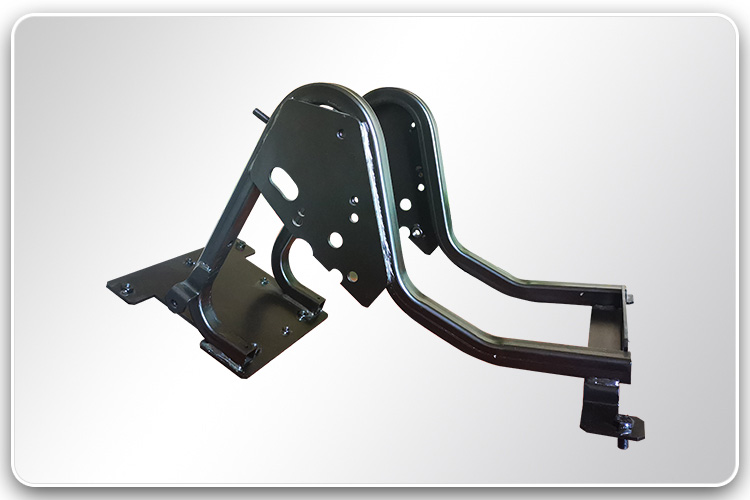

Bagian OEM Otomatis

Bagian OEM Otomatis

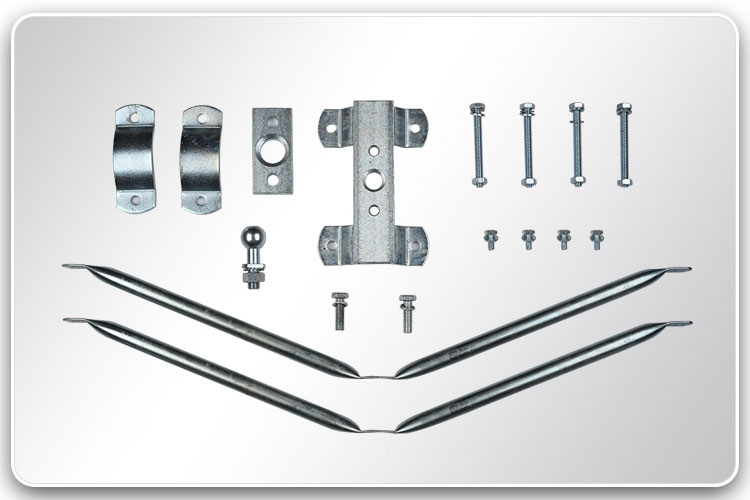

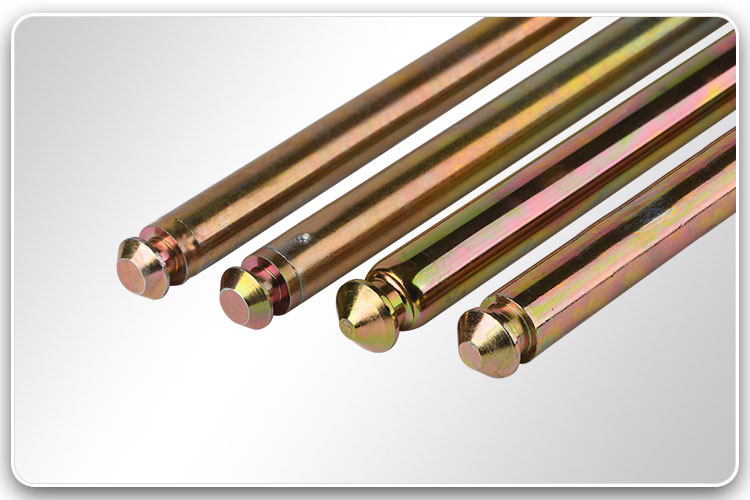

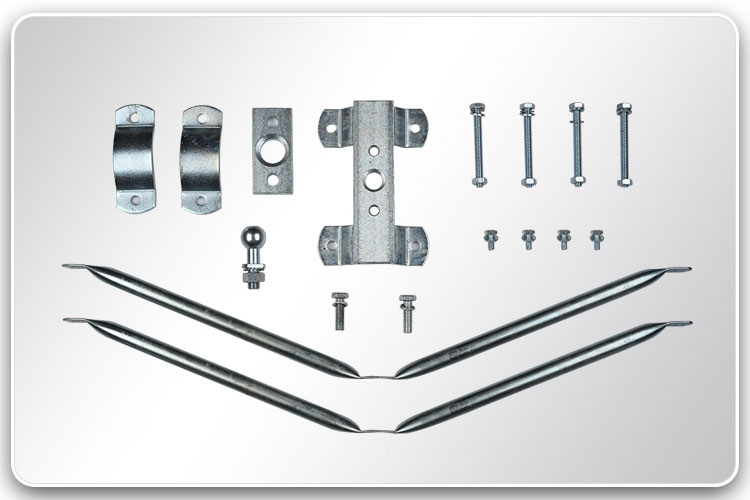

Otomotif Adjustable Torsion Bar

Otomotif Adjustable Torsion Bar

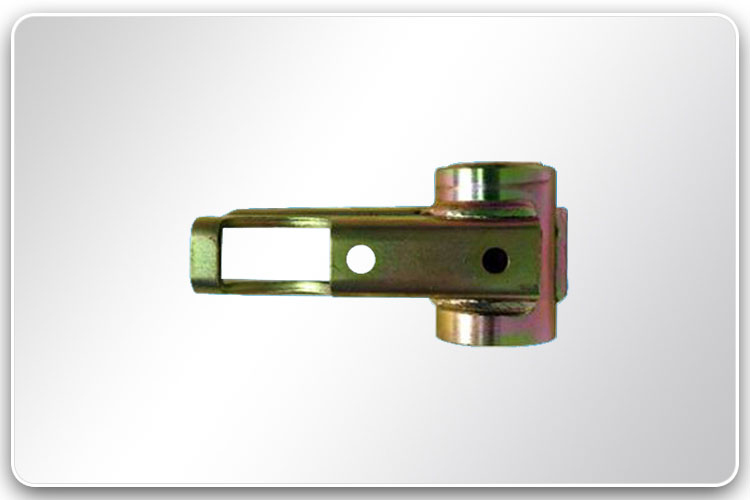

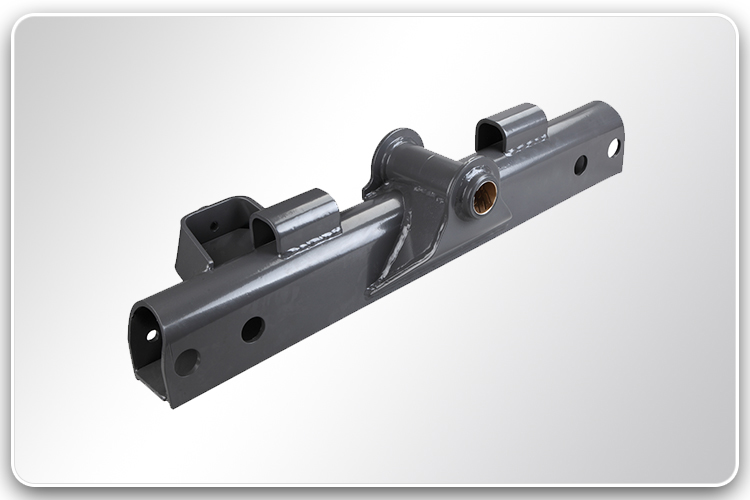

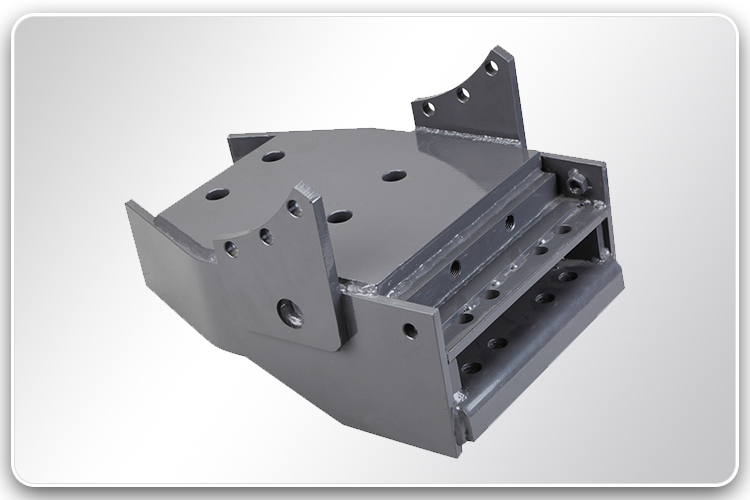

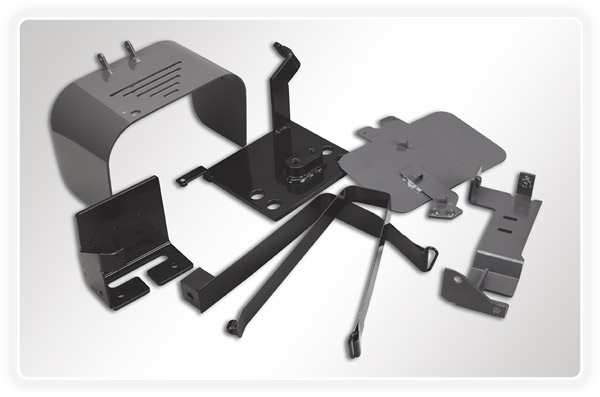

Bagian OEM Pertanian

Bagian OEM Pertanian

Braket Mirror

Braket Mirror

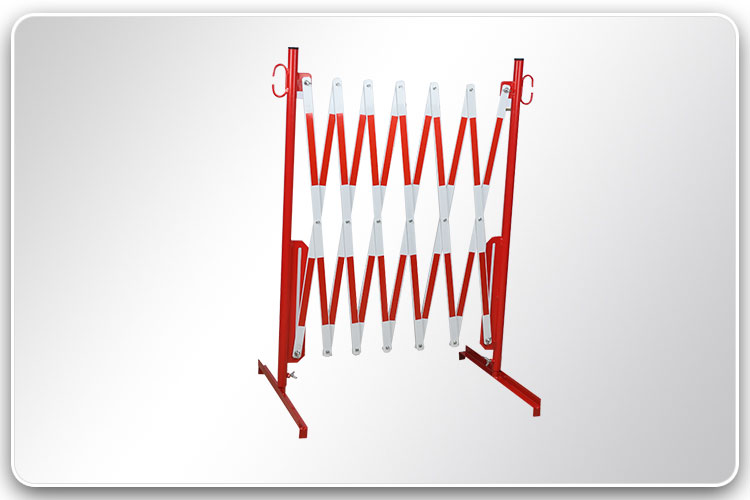

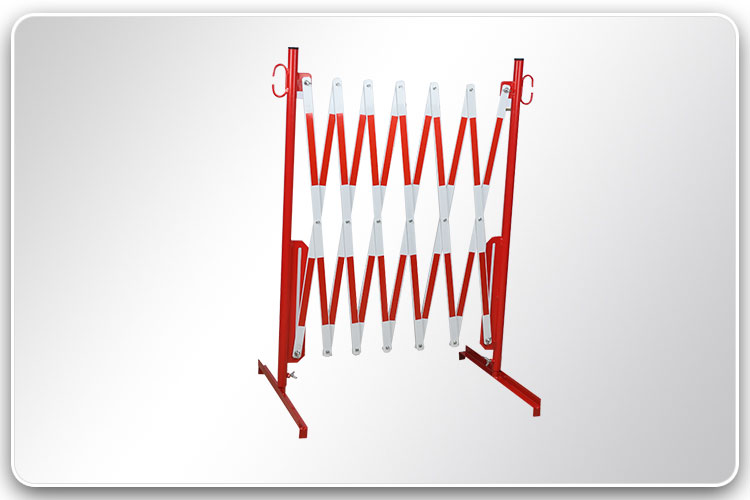

Expending Barrier Sets

Expending Barrier Sets

Pengawal Proteksi Kacilakan;

Pengawal Proteksi Kacilakan;

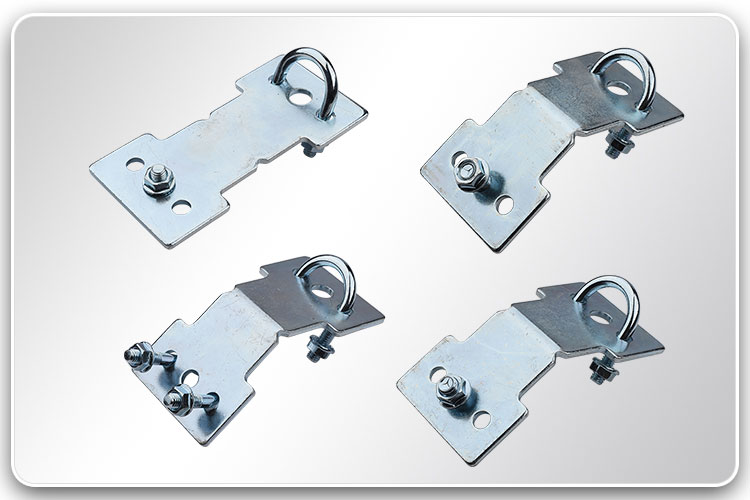

Gutter Bracket and Leaf Filter

Gutter Bracket and Leaf Filter

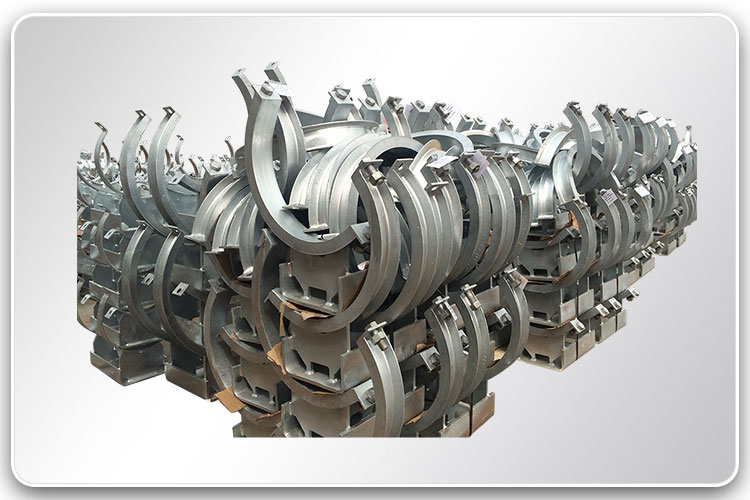

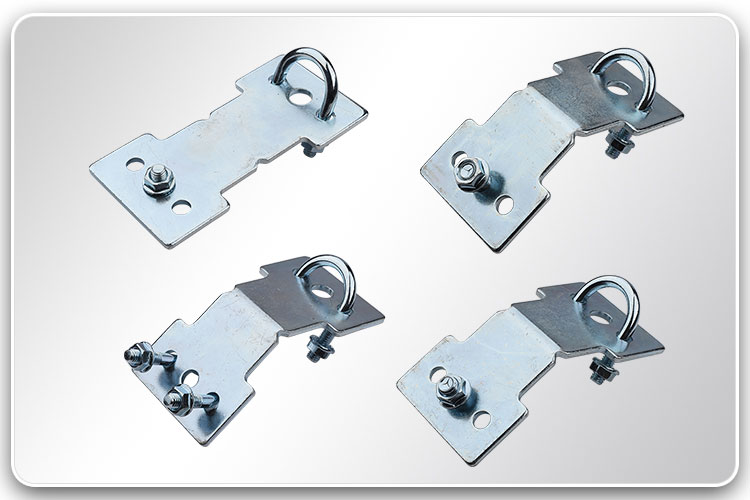

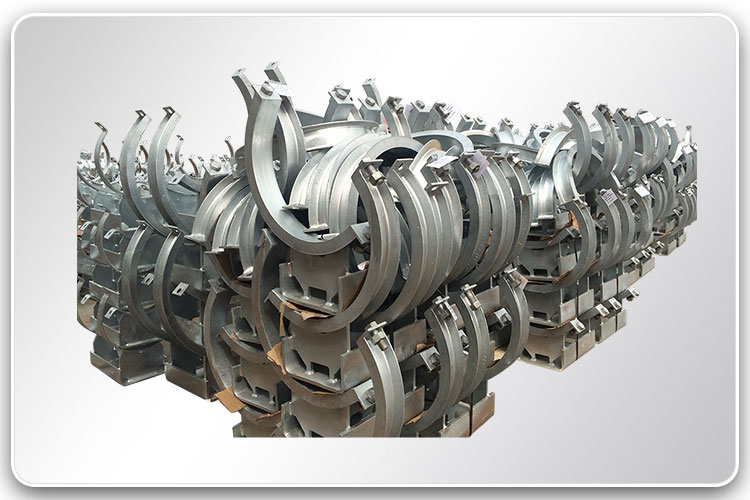

Pipe Holder

Pipe Holder

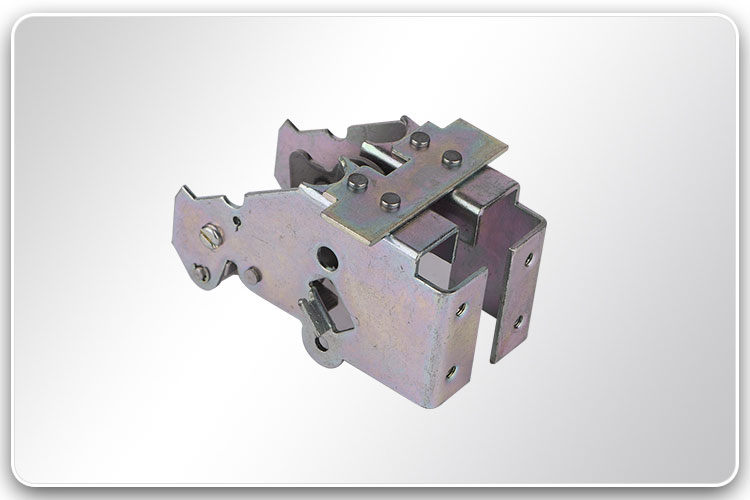

Saklar Kabinet Daya

Saklar Kabinet Daya

Garment Racking Parts

Garment Racking Parts

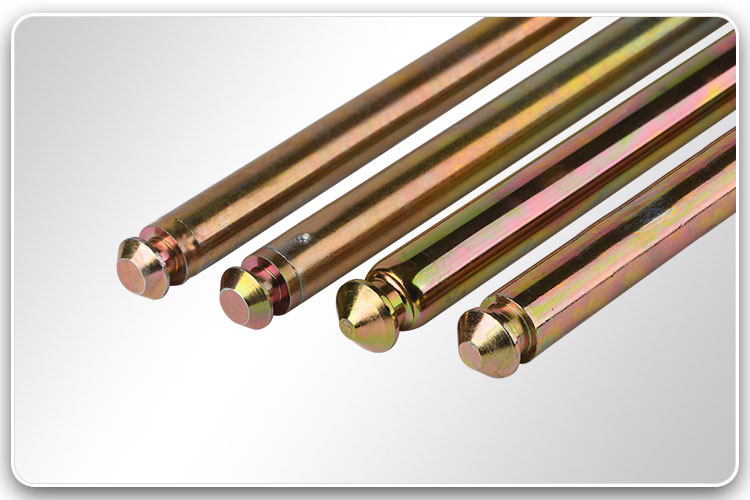

Wheelie Bin Axle

Wheelie Bin Axle

Furniture Parts

Furniture Parts

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик