Description

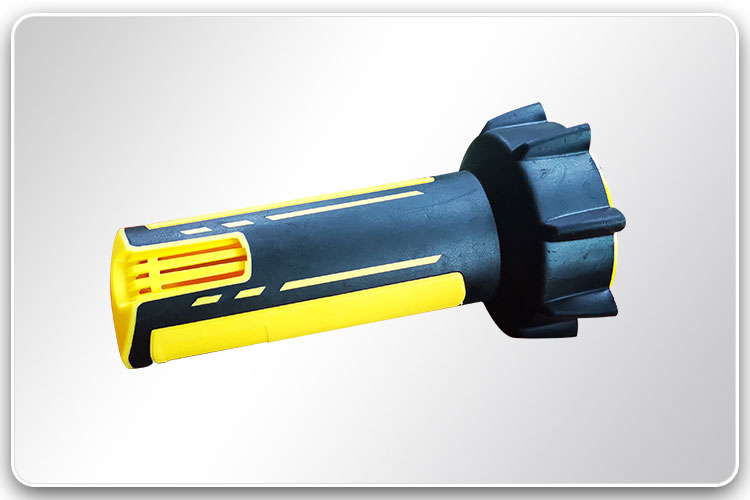

Plastic Injection Overmolding is the injection molding process where one

material (usually a TPE) is molded onto a second material (typically a rigid

plastic). If properly selected, the overmolded TPE will form a strong bond with

the plastic that is maintained in the end-use environment. The use of primers

or adhesives is no longer required to achieve an optimum bond between the two

materials.

Plastic Injection Overmolding can be used to enhance many features of

product designs, including

-Vibration damping

-Tambah ing tingkat kenyamanan

-Segel tahan banyu

-Sound absorption

-Isolasi listrik

Two injection molding processes dominate the manufacture of Plastic

Injection Overmolding: insert molding and multi-shot injection molding.

-Insert Molding

Proses paling umum kanggo Overmolding Injeksi Plastik yaiku nyetak cetakan, ing endi pre-moldedinsert dilebokake ing cetakan lan TPE langsung ditembak. Keuntungan cetakan insert yaiku mesin IM shot tunggal konvensional sing bisa digunakake (pangeluaran mesin anyar ora perlu), lan biaya perkakas sing ana gandhengane karo cetakan insert luwih murah tinimbang proses multi-shot.

-Moulding Bahan Multiple

Multiple material, uga dikenal minangka proses nembus Injeksi Plastik rong tembakan (utawa multi-shot), cetakan mbutuhake cetakan injeksi khusus mesin sing dilengkapi rong utawa luwih laras, saengga bisa ditrapake rong bahan (utawa luwih) menyang cetakan sing padha sajrone siklus cetakan padha. A molderwill milih cetakan multi-shot kanggo nyuda kaping siklus, entuk kualitas bagean sing unggul lan nyuda biaya tenaga kerja.

For Plastic Injection Overmolding process selection, in general, insert

molding is the process of choice when annual production volumes and local labor

costs are low. For higher volume production programs (over 250,000 units

annually) or areas with increased labor costs, multi-shot molding operations

are the method of choice.

Auwell nawakake cetakan insert uga proses injeksi plastik multi materi kanggo pilihan klien.

Advantages

-Pengalaman Sugih

Luwih saka 20 taun pengalaman injeksi Plastik pangembangan lan produksi produk tambahan, utamane kanggo pasar Eropa lan Amerika Utara, kanthi pemahaman sing kuat babagan standar materi, teknis lan kualitas ing saindenging jagad.

-Cepet Nguripake

Umume, kita nyedhiyakake akuotasi sajrone 3 dina kerja. Nggabungake teknologi manufaktur lan fasilitas paling anyar, Auwell bisa ngirim sampel pertama sajrone 6 minggu.

-Panyedhiya Solusi Komprehensif

Auwell nyedhiyakake layanan komprehensif kanggo proyek Injeksi Plastik Injeksi wiwit diwiwiti saka desain, liwat prototyping, pangembangan alat / perlengkapan, sampling, produksi massal, lan dhukungan logistik lan pasca jual.

-Rigid QC Policies

Kualitaspolicy sing paling ketat diwiwiti saka kontrol material, lan banjur ditindakake nganti inspeksi pangiriman pungkasan kanggo pesenan Injeksi Plastik. Sertifikat bahan kalebu sertifikat pabrik, komponen kimia pihak katelu, laporan properti mekanik, uga laporan RoHS lan REACH sing dijaluk. Westrukturisasi proses kita, nggawe Chart Flow lan Plans Kontrol produksi, priksa manawa kabeh proses QC sesuai karo ISO9001-2015kebutuhan lan spesifikasi nggambar.

-Jangka Bayaran sing Fleksibel

For tooling, the general

payment term is 50%-50%, meant 50% deposit, 50% after first sample free. For

mass production, we offer flexible payment terms, reasonable credit terms will

be given, the client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Produk sing gegandhengan

Plastic Injection Mold for Automotive Parts

Plastic Injection Mold for Automotive Parts

Plastic Injection Parts

Plastic Injection Parts

Bagean Thermoforming Plastik

Bagean Thermoforming Plastik

Karet & Moulding Silikon

Karet & Moulding Silikon

Katalog katrangan babagan bagean injeksi plastik sing digawe karo Auwell lan diwenehake kanggo para pelanggan dunya sing misuwur. Klik gambar sing cocog kanggo rincian. Elingi, umume produk mung kanggo demonstrasi.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик