Description

Die casting is a metal casting process that is characterized by forcing

molten metal under high pressure into a mold cavity. The mold cavity is created

using two hardened tool steel dies and work similarly to an injection mold

during the process. The typical material for high pressure die casting are

aluminum, zinc, magnesium, copper, and tin-based alloys. Depending on the type

of metal being cast, a hot, or cold-chamber machine is used. Auwell typically

provides services for hot chamber aluminum and zinc die casting molds and

products.

Pengecoran mati tekanan tinggi bisa ditindakake ing rongga siji utawa pirang-pirang, nggunakake unit mati utawa kombinasi mati gumantung karo syarat produk.

Different type of dies in the die casting process:

-Rongga tunggal kanggo ngasilake siji komponen

-Rong growong kanggo ngasilake bagean sing padha

-Unit die to produce different parts at one time

-Kombinasi mati kanggo ngasilake macem-macem bagean kanggo kumpulan

The casting equipment and the metal dies represent large capital costs. It

is thus especially suited for a large quantity of small to medium sized

castings, which is why high pressure die casting produces more castings than

any other casting process. High pressure die casting is characterized by an excellent

surface finish (by casting standards) and dimensional accuracy.

High pressure die casting is now considered as an industrial procedure,

used to manufacture parts for sale, or as part of machines for any other

commercial or industrial production. The process allows production of accurate

products to the desired size, shape, and thickness with tight tolerances,

making it the most simple yet effective casting process, essential for creating

metal parts with specified details and quality demands.

Pengecoran mati tekanan dhuwur kabukten migunani tumrap produk. Ing proses iki, macem-macem modifikasi bisa digawe kanggo produksi. Pabrikan mbuwang sithik dana lan luwih sithik nalika nggawe part-casting sing diprodhuksi luwih apik kanggo para pembeli.

Pengecoran mati tekanan dhuwur bisa ngilangi post-machining lan ngulang maneh. Prosese ngirit banget lan produk rampung sing digawe ing proses iki akurat lan awet.

High pressure die casting is an efficient, economical process offering a

broader range of shapes and components than any other manufacturing technique.

Parts have a long service life and may be designed to complement the visual

appeal of the surrounding part.

Kaluwihan of high-pressure die casting are as following:

-Produksi Kacepetan Dhuwur

High-pressure die casting

supports complex shapes within closer tolerances compared to many other mass

production processes. Little or no machining is required and thousands of

identical castings can be produced before additional tooling is required.

-Akurasi dimensi lan stabilitas sing apik

Cast casting die tekanan dhuwur ngasilake bagean sing awet kanthi konsistensi dimensi nalika njaga toleransi cedhak. Dheweke uga tahan panas.

-Strength and weight

Cast casting die tekanan tinggi duwe kekuatan tarik sing cukup dhuwur ing 415mpa. Casting tembok sing tipis bisa luwih entheng lan luwih entheng tinimbang corak casting liyane.

-Multiple teknik ngrampungake

Cast -arts die-pressure bisa digawe kanthi permukaan sing alus utawa tekstur, lan gampang dipasang utawa rampung kanthi persiyapan permukaan minimal.

-Déwan sing disederhanakaké

High pressure die casting

provides integral fastening elements, such as bosses and studs. Holes can be

cored and made to size using tap drills, external threads can otherwise be

cast.

Auwell offers various types of services to fulfill the clients’

requirements. We have a rich experience in designing and manufacturing high

pressure die casting tools for the worldwide market, especially EU countries. We

produce dies and cast products, including machining and surface treatment, for

our clients.

Spesifikasi Teknis

-Materi Unsur Inti

H13, 1.2344 (X40

CRMoV51), 1.2367(X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

Bahan Bolster: P20,1.2312, 1.2738

-Standard Components

HASCO, LKM standard or custom

made

-Bahan Produk Populer

AL226, AL230, AlSi10Mg,

360,380,383, 413 and A304 K-alloy, ADC12, ADC10, Zamak 3, Zamak 5, ZA-8, ZA-12

and ZA-27 etc.

-Product surface finishing

Includes but is not

limited to: brush, line polishing, high gross polishing, mirror polishing, sand

blaster, anodizing, zinc-plating, chrome-plating, nickel-plating, powder

coating, silver coating, E-coat, wet paint, silk screening and stenciling etc.

-Maximum Machining Closing

Force

4,000 tons, part weight:

5-30,000g

Kaluwihan

-Rich Experience

More than 20 years of

experience in high pressure die casting products development and production, especially

to the European and North American markets, with solid understanding of the

material, technical and quality standards worldwide.

-Fast Turnaround

Umume, kita nyedhiyakake akuotasi sajrone 3 dina kerja. Nggabungke teknologi manufaktur lan fasilitas paling anyar, Auwell bisa nyedhiyakake conto awal mung 5 minggu kanggo proyek sederhana.

-Panyedhiya Solusi Komprehensif

Auwell provides

comprehensive services for high pressure die casting projects starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and to logistic and post-sale support.

-Rigid QC Policies

Kualitaspolicy sing paling ketat diwiwiti saka kontrol material, lan banjur dipriksa nganti pungkasan. Sertifikat material kalebu sertifikat pabrik, komponen kimia pihak katelu, lan laporan properti mekanik, uga laporan RoHSand REACH sing dijaluk. Laporan liyane kalebu laporan dimensi, kekandelan perawatan lumahing, lan laporan tes kabut uyah, lsp. Kita nyusun proses, nggawe Grafik Alur lan Rencana Kontrol sadurunge produksi, nggawe kabeh proses QC sesuai karo persyaratan ISO9001-2015 lan nggambarake spesifikasi.

-Flexible Payment Term

For mass production, we

offer flexible payment terms, reasonable credit terms will be given, the client

only pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

Aplikasi

High pressure die casting products have widely been used in almost all

industrial sectors including:

-Aerospace and defense

-Otomotif

-Agriculture Machinery

-Energi

-Electronics

-Construction

-Transportasi

-Industrial

-Produk Konsumen

Katalog babagan produk casting mati tekanan tinggi yaiku sing diprodhuksi lan diwenehake dening Auwell kanggo para klien terkenal ing saindenging jagad. Klik gambar therelevant kanggo rincian. Elingi, umume produk mung kanggo demonstrasi.

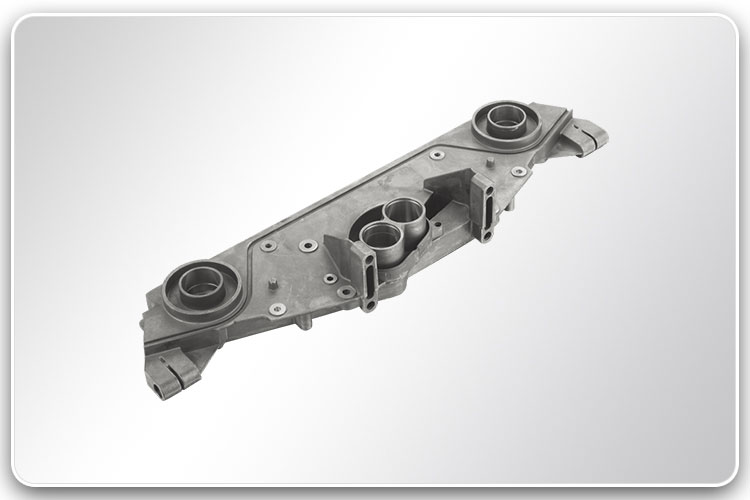

Aluminum Die Casting Otomotif Parts

Aluminum Die Casting Otomotif Parts

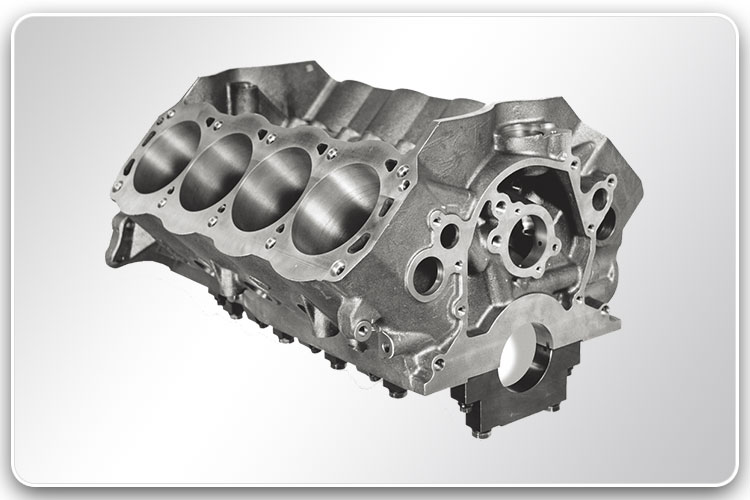

Aluminum Die Casting Industrial Parts

Aluminum Die Casting Industrial Parts

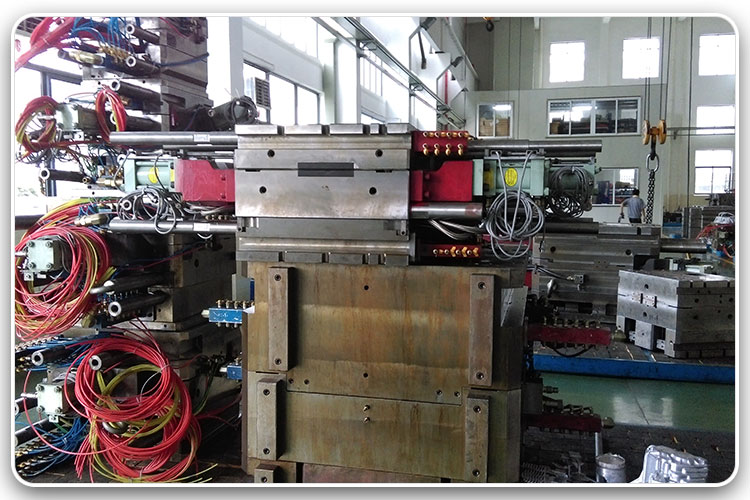

Alat Casting Die Pressure Tinggi

Alat Casting Die Pressure Tinggi

High Pressure Zinc Die Casting Parts

High Pressure Zinc Die Casting Parts

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик