Pabrik silinder mesin Auwell CNC nggawe peralatan kanthi konversilathe, mesin bubut CNC, sumbu 2 nganti 5 sumbu mesin mesin CNC, lan mesin liyane sing gegandhengan kalebu mesin grinding, mesin EDM, mesin pemotong kawat. Kita nggunakake mesin sing paling cocog kanggo produksi kanggo nggayuh efisiensi kualitas sing dikarepake.

Auwell is capable in CAM programming for high efficiency and desirable

quality for our CNC machining cylinder parts. The Auwell team can design the

necessary fixtures and tools for the milling process and test gauge for CNC

machining cylinder parts mass production quality control. CMM is available for

sample dimensional inspection. PPAP documents are available upon request.

The material for Auwell CNC machining cylinder parts mostly are high

tensile mile steel or alloy steel, in some cased, stainless steel and aluminum

could also be an option. For cost effective reasons, we use pretreatment of

extrusion, hot forging, cold forming, investment casting, die-casting for

material handle of cost-effective reasons.

Keuntungan bagean silinder mesin CNC Auwell

-Pengalaman Sugih

More than 20 years of

experience in CNC machining cylinder parts development and production,

especially to the European and North American markets, with a solid

understanding of the material, technical and quality standards worldwide.

-Cepet Nguripake

Umume, kita nyedhiyakake akuotasi kanggo bagean silinder mesin CNC sajrone 3 dina kerja. Nggabungke teknologi lan fasilitas manufaktur paling canggih, Auwell bisa nyedhiyakake fastprototypes mung sajrone 2 minggu kanggo proyek sederhana.

-Comprehensive Solution

Provider

Auwell provides

comprehensive services for CNC machining cylinder parts starting from

designing, through prototyping, tooling/fixture development, sampling, mass

production, and logistic and post-sale support.

-Rigid QC Policies

The most rigorous quality

policy for our CNC machining cylinder parts starts from material control and is

followed through to final pre-shipment inspection. Material certificates

include the mill certificate, 3rd party chemical components, and mechanical

property reports, as well as RoHS and REACH reports upon request. Other reports

include dimensional reports, surface treatment thickness, and salt fog test

reports, etc. We structure our processes, creating Flow Charts and Control

Plans before production, making sure all QC processes are in accordance with

ISO9001-2015 requirements and drawing specifications.

-Jangka Bayaran sing Fleksibel

For mass production, we

offer flexible payment terms, reasonable credit terms will be given, the client

only pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

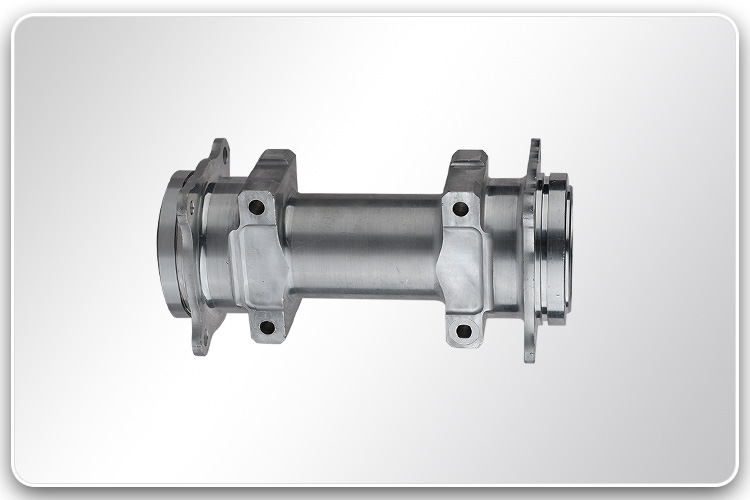

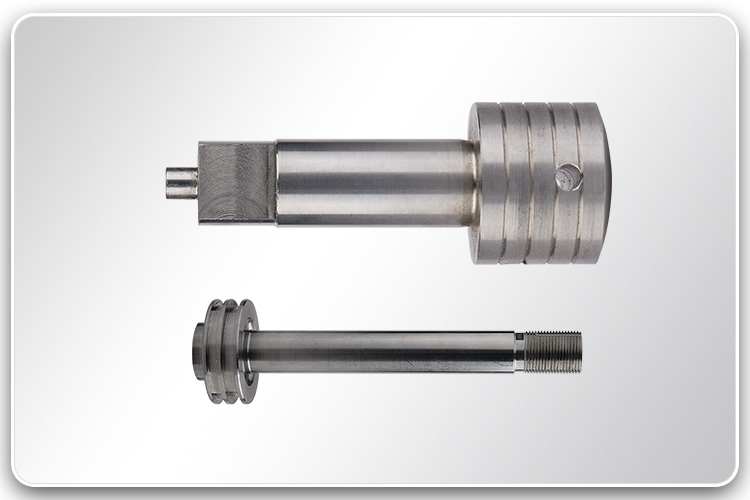

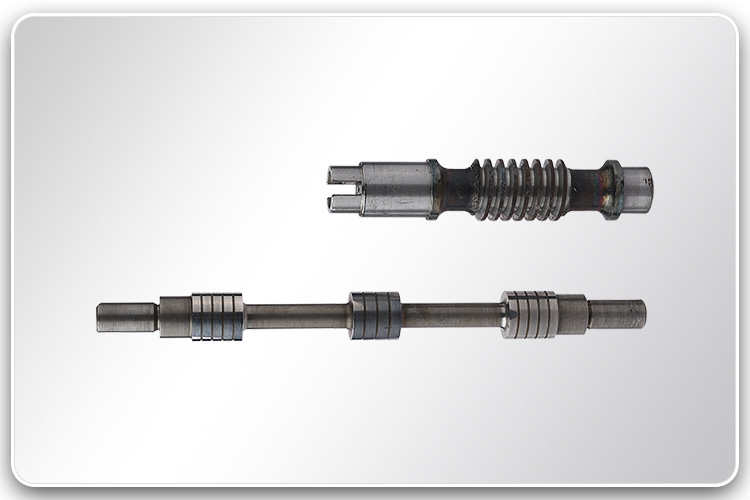

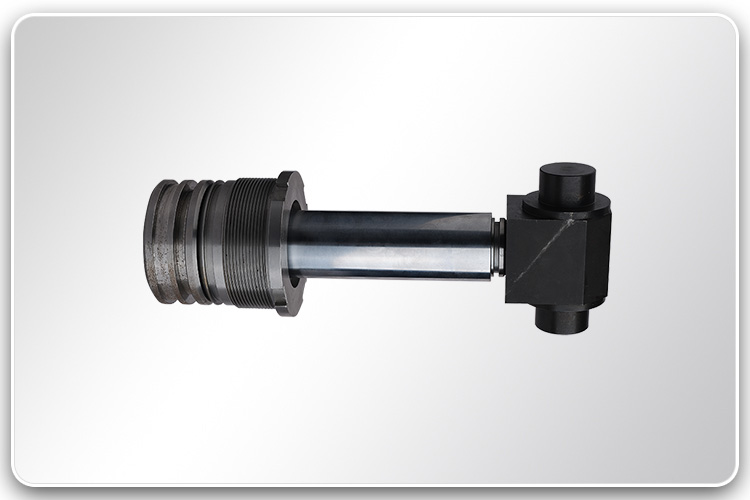

Katalog katalog silinder mesin CNC ing ngisor iki minangka sing diprodhuksi lan diwenehake dening Auwell kanggo klien sing misuwur ing saindenging jagad. Klik gambar sing cocog kanggo rincian. Mangga dielingi, umume produk mung kanggo demonstrasi.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик